Adhesive-tape manufacturers like 3M, Berry Plastics, Avery and Bemis produce their products in large, continuous rolls for convenient transport and handling. Converters thread these rolls, or webs, through processing machines like printing presses and laminating or slitting machines. The converter works closely with application engineers to select the proper adhesive product and then customizes it to meet specific design needs. During this process several questions are considered including:

- Will the adhesive be applied automatically or by hand?

- Are the design tolerances critical?

- Will the adhesive be subjected to temperature extremes (heat, humidity, UV rays)?

Transforming a large roll of adhesive into an engineered product involves extensive collaboration between the OEM engineers and the converting supplier’s engineers and machine operators. In a collaborative effort they determine the unique properties and dimensions of each adhesive product.

Some of the most common ways that adhesive tape, felt or foam can be converted include:

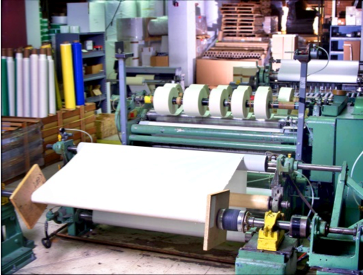

- Slitting and Rewind Slitting—This process takes the adhesive manufacturer’s large rolls and cuts them to specific widths. They can then be applied robotically or by hand.

- Die cutting—The adhesive tape gets fed through a press and cut with dies to produce a custom adhesive part. Rotary die cutting is used for large volume orders, while steel rule die cutting is used for smaller custom jobs.

- Laminating—The process of joining the adhesive to other liners and films.

Can-Do National Tape has been converting pressure- and heat-sensitive adhesive and non-adhesive tape products for over decade, producing prototype parts based on technical drawings and material specifications. Relationships we have established in the tape manufacturing industry allow us to source the best and most economical raw materials to meet application needs. Our knowledgeable sales representatives and a responsive production workforce ensure customer satisfaction. Contact us to discuss your project!