How to Protect Your Surfaces

Tapes and Films for Surface protection are extremely versatile and are used by a variety of industries including medical, aerospace, electronics, fabricators of steel and aluminum, acrylic and polycarbonate coated plastics, graphic arts, and woodworking. They carry a low to moderate tack adhesive that ensures no residue is left behind when removed.

Paper Tapes

Protective paper tapes are ideal for masking applications, like painting, printed graphics, and screen-printing. These tapes offer an easy and clean removal and come in a variety of tack levels. The Paper is available in standard to premium paper and allows for detailed die cuts and pre-spaced graphics. These paper tapes are very soft and can tear easily and sometimes require special packaging during shipment.

A latex saturated application tape with a natural rubber high tack adhesive is ideal for a clean pick-up and transfer of letterings and graphics. It’s important your protective paper lays flat to the exposed release liner so the cut graphics and die-cut letterings are protected against wrinkling, tunneling and edge curling. Our CDNT 6582 is the perfect solution giving you the control and flexibility you need.

- Low Tack: Use for pre-mask for large format digital prints.

- Medium to High Tack: Ideal choice for most sign shop applications.

- High Tack: Used with Heavy weight paper for small to medium graphics.

- High Tack Layflat: Lays flat on silicone release liners and is ideal for most sign shop applications.

- Pallet Tape: Protects print surfaces of textile screen print equipment to extend the life of the pallet.

- Painter’s Tape: Is used for a clean release after painting of walls, wood trim, glass, woodwork, metal, etc.

Protective Films

Originally designed for window protection, protective films are transparent and shield against the environment, including dirt, moisture, and human handling. Protective films are residue free, protects non-porous surfaces, prevents scratches and abrasions, and is transparent. It is often used to protect windows, flooring (including floorboards and carpets), and finished metals and plastics during mechanical processes, storage, and transportation.

Protective films can be used for permanent or temporary applications on solid surfaces. Substrates involved can be lacquered plates, plastics, glass, laminates and reflective aluminum. They can be applied by machine or hand and are available in a variety of widths to fit your application. A high transparency makes this product suitable for the protection of more critical surfaces where high esthetical appearance is required.

Low Tack Film: Used for pre-mask for medium to large sized vinyl graphics.

Medium Tack Film: Best choice for most sign shop applications.

Medium Tack and Easy to Tear Film: Designed for simplified applications.

High Tack Film: Best for small vinyl graphics and lettering

Here’s a look at how a variety of industries utilizes protective tapes and films.

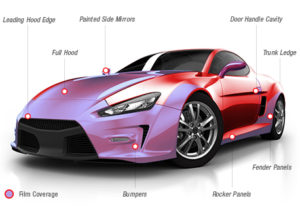

Protecting Surfaces within the Automotive Industry

The automotive industry uses surface protection tapes and films in a variety of ways, including masking of mirrors and door panels during assembly and delivery to the dealer.

Latex-saturated protective paper can be hand or die-cut for specialty detail painting such as pin-striping. It is designed to prevent paint from bleeding through, allowing for a clean, sharp edge. These tapes are also designed to be applied by machine or by hand. Depending on the environment, these protective tapes are designed for low-temperature performance as well as high-heat applications, withstanding temperatures as high as 400 degrees F. Additional characteristics can include resistance to flame and corrosion for harsh environments.

Urethane protective films are strong, durable, and virtually invisible, and keeps vehicles looking newer longer. These films create a barrier to protect vulnerable areas such as front bumpers, hoods, side mirrors, panels, and more. Autowrap films are used when final removal of the film will be completed at the dealer. These custom wraps needs to be tested and approved to withstand exposure to the elements.

In addition to protecting the exterior, automotive manufacturers want to protect a car’s interior as well. Protective tapes used in the interior must adhere to a wide variety of materials and textures, remove quickly and cleanly with no adhesive residue, and resist thermal degradation when exposed to high interior temperatures.

Protecting Surfaces within the Aerospace Industry

Protective tapes and films are used in a variety of applications in the aerospace industry. The higher grade protective tapes are used for aircraft painting and stripping. These tapes are solvent resistant and protect windows, hatches, and other areas during painting and stripping. Surface protection products can also be used to refurbish aircraft components and moisture barrier products and help secure seams in aircraft air conditioning, aircraft duct and air handling systems, and galley.

Protection of Carpets

Carpet protective films utilize a puncture resistant film and a specialty adhesive. These protective films offer a quick adhesion to carpets with no floating and are easily removed without any residue after extended application. These products can be printed and used for automotive applications or reverse wound for quick and efficient commercial installation.

There are many great advancements happening with surface protection tape and films and Can-Do National Tape is excited to be a part of it. We will help you find cost and time saving solutions for your application. Give us a call to see how we CAN convert your ideas into reality.