Topic: The Correct PSA Tape for your Substrate

Since adhesives simply join two surface areas, unlike other bonding methods that alter the surface (i.e. welding, solvent activation, fasteners), there are a number of surface conditions that need to be considered for the adhesive to be effective. Is the surface rough or smooth? How porous is the surface? Are there any coatings on the surface? How clean is it? How much flexibility does it have or require? How big or small is the surface? What environmental conditions will it be exposed to? What is the surface energy?

Start with the Substrate

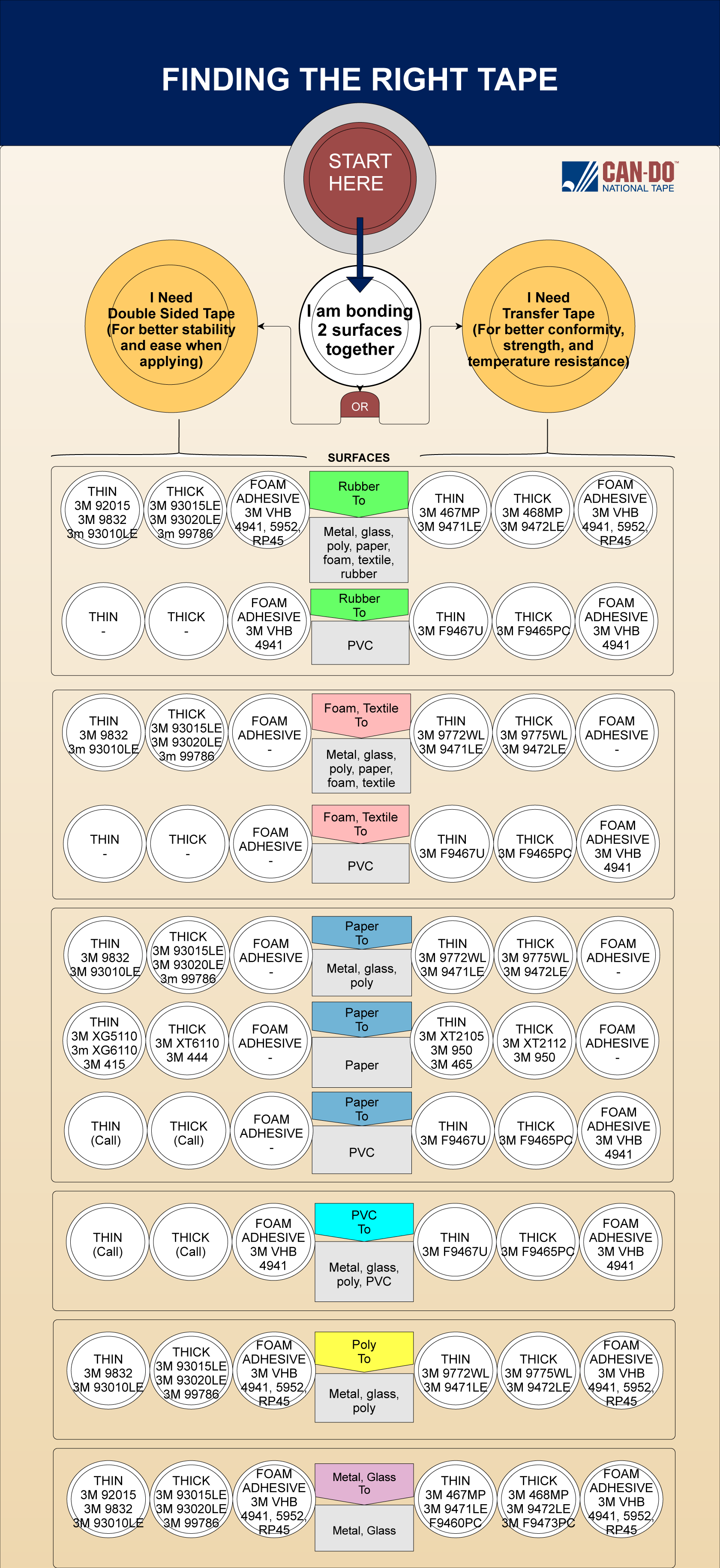

The start of your journey to finding the right PSA Tape for your application will always begin with the substrate. Below is an infographic displaying the correct 3M Tape to could use to bond together two surfaces.

If the above infographic of substrates and PSA tape does not have your application, heat or water activated tapes may be your solution. Heat activated tapes work well with rubber and plastic materials. They are ideal for induction curing and sealing. Water activated tapes are cost effective and environmentally friendly. They are ideally suited for corrugated boxes and show obvious signs when they’ve been tampered with.

The Importance of Environmental Conditions

Environmental conditions will affect the performance of your bond. If your application will be exposed to dirt, wind, rain, or extreme temperatures, you will want a specially formulated adhesive tape to withstand these conditions.

-

CHEMICAL-RESISTANT ADHESIVE TAPES

- Chemicals and solvents can break down and degrade adhesives. Chemical-resistant tapes are formulated to resist these effects and are ideal for laboratories, printing processes, painting applications, and manufacturing processes involving chemicals.

-

WATER-RESISTANT ADHESIVE TAPES

- Water-resistant tapes deliver great performance when exposed to water or wet conditions. Water-resistant tapes can be used for weather stripping, packing materials, automotive assemblies, marine applications, and many other uses involving damp conditions.

-

HEAT-RESISTANT ADHESIVE TAPES

- When a bond is exposed to high heat, like in appliances, automotive components, or labels, heat-resistant adhesive tapes are essential.

-

UV RESISTANT ADHESIVE TAPES

- A special combination of engineered film backings and acrylic adhesives provide dependable protection against UV degradation. These adhesive tapes are effective for construction and building materials, outdoor signage, and window and door stickers.

The Importance of Surface Energy

The molecular force of attraction between two unlike materials determines their adhesion. You will get a stronger adhesion with high surface energy (strong molecular attraction). To understand surface energy, consider water on the hood of an un-waxed car. Due to the high surface energy of the un-waxed surface, the water flows and pools on the hood. Comparatively, water on a waxed hood with low surface energy beads up. Adhesive works in a similar way. On surfaces with high surface energy, the adhesive flows and “wets out” the surface, which is needed to create a strong bond. However, having a low surface energy does not mean adhesive is not an option. There are many adhesives that have been specifically formulated for low surface energy surfaces.

While one of the biggest advantages of adhesives is the ability to bond dissimilar substrates together, it’s important to find the RIGHT adhesive to do so. You must consider the material, application, and environmental variables, like temperature tolerance or chemical resistance. Our team of experts at Can-Do National Tape understands all of these variables and will help you find the best adhesive solution for your application.

Don’t spend any more time trying to find the solution on your own. Call us today to speak with a sales representative and start building your customized adhesive tape solution.

We Can Convert Your Ideas Into Reality! Call us at 1-800-643-5996